Also see Dip Spin Specifications

SWD Inc. provides dip spin coating services designed for precision, performance, and sustainability. As a trusted partner to manufacturers across industries, we specialize in precision dip coating for fasteners and small metal components. This process ensures uniform coverage, chemical resistance, and corrosion protection while preserving part geometry and tolerances.

With decades of experience and a strong commitment to environmental responsibility, SWD applies high-quality coatings using advanced equipment and trusted materials from brands like MAGNI and Dörken (Doerken). Our mission is to provide world-class, customer-focused solutions that consistently exceed expectations and support long-term growth.

What Is Dip Spin Coating?

Dip spin coating is a highly controlled finishing process that enables efficient, uniform coating of bulk quantities of small parts. At SWD, every part begins with a cleaning and pretreatment phase to remove surface contaminants and heat treat scale. Once prepared, parts are placed in a fully automated line that feeds the parts into a coating basket, submerged in a coating material, and spun and tilted to remove excess material. The parts are then cured in a high-efficiency oven to complete the application.

We control variables such as immersion time, spin speed, tilt and direction, coating viscosity, and cure cycle to customize the process for each part. This level of control allows for repeatable and high-quality results. Our system is compatible with all major coatings used in fastener finishing.

Benefits of dip spin coating include:

- Provides complete and uniform coverage

- Prevents thread fill and clogging in recesses

- Eliminates the risk of hydrogen embrittlement

- Enhances resistance to chemicals and corrosion

- Consistent Torque and Tension

- Offers a cost-effective solution for high-volume part finishing

Dip spin coating services provide a reliable and economical method for applying high-performance finishes to small components without compromising functional features.

Ideal Industry Applications

Precision dip coating works well with a variety of base materials, including:

- Steel

- Stainless steel

- Aluminum

- Die-cast metals

Some parts respond better to dip spin methods than to spin-only coating systems, especially those with intricate geometries or small recesses. Dip spin coating helps improve consistency and reduce finishing issues across a wide range of industries and applications, including:

- Automotive

- Aerospace

- Consumer electronics

- Firearms

- Industrial valves

- Oil and gas

- Agricultural machinery

- Heavy equipment

SWD’s Dip Spin Coating Capabilities

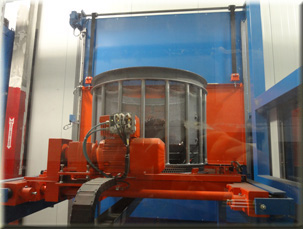

At SWD, we have designed an advanced dip spin system that addresses common issues found in older methods. Our system uses baskets that not only spin but also tilt, which allows excess coating to drain effectively from deep recesses and threaded cavities. We also offer planetary dip spin processing which can further enhance coating thickness on even the most complex geometries. During curing, parts are evenly spread across vibrating trays to reduce touch points and coating imperfections. We rely on trusted coating systems from MAGNI and Dörken (Doerken) to ensure consistent, high-quality results.

Key Features

- Custom corrosion protection based on part design and performance needs

- Elimination of hydrogen embrittlement

- Environmentally responsible, RoHS and REACH compliant processes

- Consistent Torque values for fasteners

- Thread fill prevention to preserve proper fit and function

When parts are being assembled it is vital to provide a consistent torque range to ensure the fasteners are meeting the calculated clamp load. At SWD Inc. we verify each specification we process actually meets the specified torque tension range in our A2LA accredited laboratory. Surrogate bolts are used to verify torque tension values per specification as well as coating thickness. We also verify salt spray and humidity testing to ensure the corrosion protection will meet or exceed specification. Further AIAG CQI-12 is used as an auditing benchmark for our processing.

When parts are being assembled it is vital to provide a consistent torque range to ensure the fasteners are meeting the calculated clamp load. At SWD Inc. we verify each specification we process actually meets the specified torque tension range in our A2LA accredited laboratory. Surrogate bolts are used to verify torque tension values per specification as well as coating thickness. We also verify salt spray and humidity testing to ensure the corrosion protection will meet or exceed specification. Further AIAG CQI-12 is used as an auditing benchmark for our processing. Doerken Coating Systems

DELTA-PROTEKT® KL 100 & KL 105

DELTA®-TONE 9000 (basecoats)

DELTA-PROTEKT® KL 100 is a largely inorganic coating which forms a micro layer basecoat filled with zinc and aluminum lamella. It represents the next generation to the proven DELTA®-TONE 9000 zinc-flake coating. With a coating thickness reduced to 8µm, DELTA-PROTEKT® KL 100 achieves corrosion resistance times in excess of 600 hours.

DELTA-PROTEKT® VH 300 series (topcoats)

DELTA-PROTEKT® VH 300 is an inorganic secondary sealant which contains silicate and can be diluted with water. With a coating of only 1 to 3 µm, this product delays the effect of atmospheric substances such as moisture or oxygen and resists attack from various chemicals.

DELTA®-SEAL

DELTA®-SEAL is a highly cross-linked organic micro-layer, which makes the system highly resistant to chemical attack and is suitable for flexible work pieces. It can be used both as a sealant on an inorganic basecoat and a coating by itself on a surface after suitable pre-treatment. DELTA®-SEAL is particularly suitable for re-usable bolted joints. In addition, you can choose from a wide range of colors.

Magni 554

Developed with the OEM in mind

Magni 554 is a chrome-free fastener duplex coating system that combines an inorganic zinc-rich basecoat with an organic aluminum-rich friction-modified topcoat. The inorganic basecoat system is developed for superior heat-resistant corrosion performance and consistent in-process material stability. The organic topcoat system can be adjusted to meet OEM friction requirements while providing outstanding adhesion, heated loosening performance and chemical resistance. Magni 554 is applied at SWD with a state of the art tilt and tumble dip-spin method with fewer processing steps, resulting in improved quality at a lower cost.

Magni 554 is a chrome-free fastener duplex coating system that combines an inorganic zinc-rich basecoat with an organic aluminum-rich friction-modified topcoat. The inorganic basecoat system is developed for superior heat-resistant corrosion performance and consistent in-process material stability. The organic topcoat system can be adjusted to meet OEM friction requirements while providing outstanding adhesion, heated loosening performance and chemical resistance. Magni 554 is applied at SWD with a state of the art tilt and tumble dip-spin method with fewer processing steps, resulting in improved quality at a lower cost. MAGNI 565

Magni 565 is a chrome-free duplex coating that combines an inorganic zinc-rich basecoat with an aluminum-rich organic topcoat. Formulated as a two-coat system and resistant to automotive fuels and fluids, Magni 565 is the preferred fastener coating of leading global automotive manufacturers. It provides superior corrosion protection and cost-effectiveness and is typically applied to externally threaded fasteners, stampings and other hardware.

Applied via dip-spin or spray application methods

Alleviates hydrogen embrittlement concerns

Excellent bimetallic corrosion resistance

Paintable

RoHS, WEEE and ELV compliant

MAGNI 501

Magni 501 is a globally available chrome-free, inorganic zinc-rich corrosion protection coating engineered for use on fasteners and other metal components. An ideal replacement coating for zinc plating and trivalent passivation, Magni 501 is applied as a thin, paintable coat that provides exceptional corrosion protection in a single layer. The result is superior performance compared to conventional zinc plating.

Alleviates hydrogen embrittlement concerns

Applied via dip-spin with tilt and tumble to minimize recess fill

Excellent protection against aluminum

Consistent torque-tension relationship

Resistant to automotive fuels and fluids

RoHS, WEEE, ELV and REACH compliant

Dip Spin Coating Services from SWD Inc.

As a leader in dip spin coating services, SWD Inc. brings technical precision and a customer-first mindset to every project. Our team is known for delivering consistent, high-quality results, backed by a strong reputation for reliable service.

Our company’s mission includes supporting sustainable manufacturing, promoting employee development and safety, and maintaining our role as a responsible member of the community. We are committed to helping our customers grow and succeed by offering dependable precision dip coating backed by innovation and integrity. Find out what Better4 is all about.

Let SWD Finish…What you started! Request a quote to start your project.